Understanding NTEP Compliance: A Guide for Weighing Equipment Buyers

NTEP compliance ensures your weighing equipment meets national accuracy standards, crucial for avoiding legal penalties and ensuring fair transactions. This article will explain what NTEP compliance is and why it’s essential for your business.

Key Takeaways

-

NTEP compliance is crucial for businesses to ensure that weighing equipment meets legal standards, preventing fines and maintaining consumer trust.

-

Using NTEP-approved scales enhances accuracy in transactions, fostering operational efficiency and reducing the risk of financial discrepancies.

-

Regular maintenance and calibration of NTEP-certified scales are essential to uphold compliance and guarantee consistent measurement accuracy.

Understanding NTEP Compliance: A Guide for Weighing Equipment Buyers

Navigating the world of weighing and measuring devices can be complex, especially when legal compliance is at stake. The National Type Evaluation Program (NTEP) plays a pivotal role in ensuring that weighing equipment used in commercial transactions meets the stringent standards necessary for legal-for-trade status. This certification process is not just a bureaucratic hurdle; it ensures that businesses adhere to local and national regulations, guaranteeing accurate weight measurements and maintaining consumer trust.

Using non-compliant weighing devices can lead to significant legal issues, including hefty fines and penalties. Businesses caught using scales that do not meet NTEP standards risk not only financial losses but also damage to their reputation. Therefore, understanding NTEP compliance is essential for any business involved in buying or selling products by weight.

Introduction

Avoiding fines and maintaining legal compliance are critical for any business, and this is particularly true when it comes to using weighing equipment. Compliance with NTEP standards helps businesses avoid legal penalties associated with incorrect weight measurements, ensuring that every transaction is fair and accurate. This blog post will focus on the significance of using NTEP-approved scales, helping you understand the legal landscape and how to navigate it effectively.

Adhering to standards set by the National Conference on Weights and Measures and the National Institute of Standards and Technology ensures businesses operate within the law. This not only protects against fines but also fosters trust with consumers by guaranteeing the accuracy and reliability of weight measurements in trade.

Understanding the importance of NTEP compliance can be the key to avoiding fines and maintaining a reputable business.

What is NTEP Compliance?

NTEP compliance refers to the certification process that ensures weighing devices are legally approved for commercial transactions. This compliance is crucial because many state and local regulations mandate the use of NTEP-certified scales to ensure fair trade practices. These scales must meet rigorous accuracy and performance criteria, providing reliable measurements that can be trusted by both buyers and sellers.

Using non-compliant weighing devices can jeopardize business operations by leading to legal issues and financial penalties. The National Type Evaluation Program certifies that a class i weighing device meets the necessary standards, protecting businesses from the risks associated with inaccurate weight measurements.

Thus, NTEP certification is not just a regulatory requirement but a safeguard for your business’s integrity and legal standing.

Key Benefits of Using NTEP-Approved Scales

NTEP-approved scales offer a multitude of benefits that extend beyond mere compliance. One of the primary advantages is the increased consumer trust that comes from guaranteeing the accuracy and reliability of weight measurements in trade. This trust is crucial for maintaining a positive reputation and ensuring repeat business.

Moreover, NTEP-certified scales are designed for precision, significantly reducing errors in transactions and enhancing operational efficiency. Legal-for-trade scales protect against financial discrepancies, ensure accurate pricing, and prevent potential losses. This not only improves the bottom line but also fosters better customer relationships by demonstrating a commitment to accuracy and reliability.

How NTEP Certification Works

The NTEP certification process is essential for all scales used in U.S. commercial transactions. It begins with:

-

Submitting an appropriate application to the National Conference on Weights and Measures (NCWM), along with the required fees.

-

Once the application is received, it is assigned a Control Number.

-

A designated laboratory is assigned to conduct the evaluation.

Communication with the assigned laboratory is crucial to discuss testing requirements and schedule the delivery of the device for evaluation. If the device passes the evaluation, a Certificate of Conformance is drafted and must be approved by the NTEP Administrator before being published. However, if the device fails the evaluation, the applicant has ninety days to correct the issues and resubmit the device for reassessment.

This rigorous process ensures that only calibrated scales meeting the highest standards of accuracy and performance are certified, providing businesses with the determined assurance that their weighing devices are compliant and reliable.

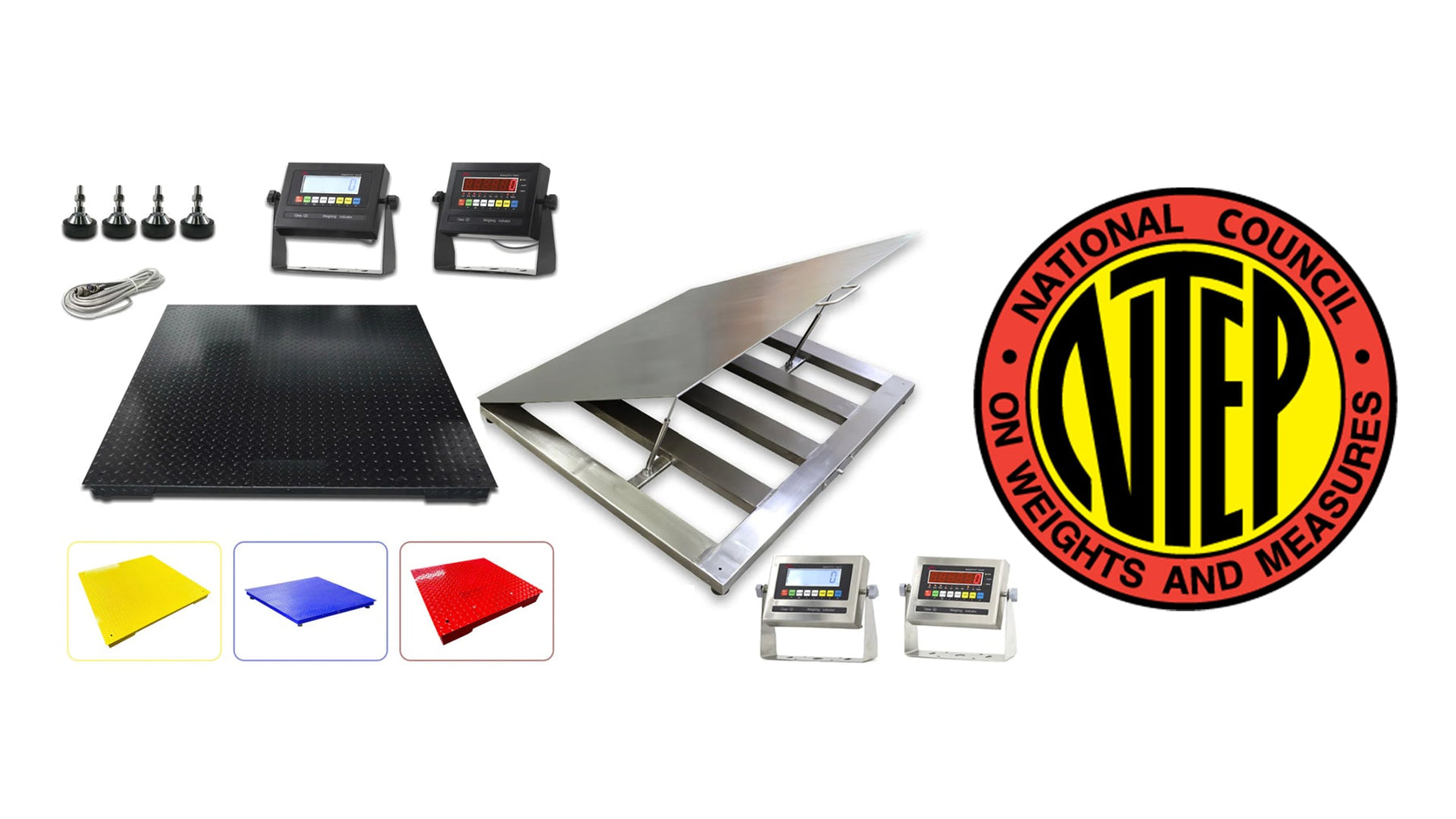

Types of NTEP-Approved Scales

NTEP-approved scales come in different types to meet the specific needs of different commercial applications. From heavy-duty floor scales used in industrial settings to portable pallet scales ideal for logistics and warehouse use, there is a wide range of legal-for-trade scales available.

Additionally, other legal-for-trade devices, such as load cells, precision balances, and force gauges, ensure businesses achieve precise measurements in various contexts.

Floor Scales

Floor scales are essential for weighing heavy-duty items in warehouses and factories, ensuring precision and reliability in operations. Common platform sizes for large floor scales include 4x4 feet, 5x5 feet, and larger, with typical load capacity ranges between 2,500 to 10,000 pounds. Custom configurations are also available for higher capacities, catering to specific commercial needs.

These scales are constructed from durable material such as reinforced steel and corrosion-resistant components, which influence their longevity and performance. Safety features, including anti-slip surfaces, overload protection, and adjustable leveling feet, are standard to ensure safe and accurate operation.

Portable Pallet Scales

Portable pallet scales offer unparalleled flexibility and ease of use across various environments. These scales are designed for easy relocation, making them ideal for businesses that require frequent movement of weighing equipment and container use in the lab.

Their versatility allows for seamless operation in different city location, enhancing operational efficiency and adaptability in shape that was created.

Other Legal-for-Trade Devices

Beyond traditional scales, NTEP certification extends to a variety of weighing devices, including load cells, precision balances, and force gauges. These devices serve distinct purposes, such as measuring weight, force, or tension in complex industrial processes, enhancing their versatility and application.

Integrating a range of NTEP-approved measuring devices ensures businesses achieve precise measurements that comply with legal standards. This not only mitigates risks associated with measurement inaccuracies but also fosters better operational efficiency and compliance, leading to accurate readings.

Ensuring Ongoing Accuracy and Maintenance

Maintaining the accuracy and reliability of NTEP-approved scales involves:

-

Regular maintenance and calibration

-

Paying annual maintenance fees to keep NTEP certification active

-

Considering the overall cost of ownership, which includes these ongoing expenses

Selecting suppliers who offer comprehensive maintenance and calibration support is crucial for ensuring the longevity and performance of your weighing equipment.

Routine Calibration

Routine calibration is essential to maintain compliance and ensure the accuracy of industrial scales over time. Recommendations for floor scale calibration include:

-

Calibrate and inspect floor scales every 6 to 12 months to maintain their accuracy.

-

Have calibration performed by professionals.

-

Use certified weights during calibration to ensure precision and adherence to legal standards.

Investing in high-quality certified scales can mitigate long-term financial risks associated with inaccurate measurements and compliance issues. Regular calibration not only ensures ongoing accuracy but also helps in maintaining the certification status of your weighing equipment.

Maintenance Best Practices

Periodic calibration and re-certification are essential for maintaining test weights’ accuracy. Test weights should be stored in their original packaging or secure weight cases near the balance to protect them from environmental factors that could affect their accuracy.

Using high-quality NTEP scales can lead to substantial long-term cost reductions by minimizing the frequency of repairs and replacements. Investing in durable and reputable scale models reduces the need for frequent calibrations and repairs, reflecting the importance of quality equipment in maintaining operational efficiency.

Legal and Regulatory Considerations

Compliance with weighing device regulations is critical to avoiding significant penalties and legal actions against businesses. NTEP certification helps businesses adhere to national weight regulations, ensuring accurate weight transactions and protecting against financial losses.

Utilizing NTEP-certified scales ensures adherence to legal standards, significantly boosting operational effectiveness and compliance.

Trade Scale Laws

Local and state weights and measures departments enforce legal standards for trade weighing to ensure fair practices. Re-certification of weighing devices may be mandated by local laws to ensure ongoing compliance. The Weight Calibration Certificate, which verifies the scale’s accuracy, is critical for compliance verification.

It is essential to verify the NTEP certification when purchasing weighing scales to ensure they meet legal standards and reduce the likelihood of discrepancies in transactions. Handbook 44 outlines the specific requirements for trade weighing equipment, ensuring businesses remain compliant with trade scale laws.

Certification and Re-Certification Requirements

Certification by the National Type Evaluation Program ensures that NTEP floor scales meet legal requirements for trade use. The Weight Calibration Certificate, which includes uncertainty of measurement, actual mass values or corrections, and environmental conditions, provides traceability to the SI through NIST.

Local regulations may require recurring inspections or re-certification for NTEP-certified scales to ensure ongoing compliance. Suppliers like Alpha-Liberty offer accredited weight documentation as part of their certification services, ensuring that businesses maintain compliance with legal standards.

Integration with Business Operations

Integrating NTEP-certified scales into business operations can significantly enhance operational efficiency and compliance with trade laws. Proper site preparation, calibration, and regular maintenance play a vital role in the performance and longevity of scales, ensuring accurate and reliable measurements.

Enhancing Operational Efficiency

Reliable scales are essential for improving operational efficiency in businesses. Using accurate and reliable scales directly impacts productivity by reducing errors in weight measurements, leading to smoother commercial transactions. Legal-for-trade scales simplify processes and help minimize the risk of errors, ensuring compliance with trade laws and avoiding potential penalties.

Businesses that utilize reliable scales enjoy better compliance with trade laws, avoiding potential penalties and enhancing overall operational efficiency. The use of NTEP-certified scales ensures that every transaction is accurate, fostering trust and reliability in customer relationships.

Data Management and Reporting

Digital integration of weighing systems allows for improved tracking and analysis of weight data across operations. This capability enables real-time data analytics, enhancing visibility and tracking for businesses, and ensuring compliance with conformance databases.

Cost Considerations of NTEP-Approved Scales

Understanding the costs associated with NTEP-certified scales is vital for making informed purchasing decisions. While the initial investment may vary based on factors such as type, capacity, and brand, the long-term savings from reduced maintenance and repair costs make these scales a valuable addition to any business.

Initial Investment

Purchasing NTEP-approved scales involves varied upfront costs depending on their type, capacity, and manufacturer. The cost of acquiring these scales can vary significantly, with factors such as the scale’s type, capacity, and brand reputation playing a major role.

Investing in high-quality NTEP-certified scales might seem expensive initially, but it ensures compliance with trade laws and provides accurate and reliable measurements, which are crucial for business operations. By understanding these factors, businesses can make more informed decisions and choose scales that meet their specific needs and budget.

Long-Term Savings

Investing in NTEP-approved scales can lead to substantial cost benefits over time due to their durability and accuracy. High-quality scales typically result in lower operational costs because they require fewer repairs and less frequent calibrations, ensuring long-lasting performance.

When considering the purchase of a floor weighing scale, it’s important to account for long-term costs associated with maintenance, calibration, and potential downtime. Buying a durable and reputable scale model reduces these long-term costs, emphasizing the importance of investing in quality equipment.

Finding NTEP-Approved Scales

Various retailers and suppliers offer NTEP-certified scales, making it easier for businesses to find suitable weighing equipment. Notable suppliers such as Scales Plus and Prime USA Scales provide a wide range of NTEP-certified weighing solutions for different industries.

Choosing reliable suppliers is essential for ensuring compliance and quality.

Local vs. Online Retailers

When selecting a supplier for weighing equipment, consider their reputation and customer reviews to gauge reliability. While local retailers offer quicker installation and immediate support, online retailers often provide a wider range of options and competitive price to weigh. The equipment can be easily installed to meet your needs.

Customer support is a critical factor that can significantly impact your overall experience and satisfaction.

Choosing a Reputable Supplier

Selecting a reputable supplier for NTEP-certified scales is crucial for ensuring compliance and quality. Suppliers like Liberty Scales are known for their comprehensive customer support and guidance in selecting the right equipment.

Choosing a trusted supplier helps businesses achieve lower cost and maintain compliance with trade laws.

When to Upgrade Your Weighing Equipment

Knowing when to upgrade your weighing equipment is essential for maintaining accuracy and compliance. Indicators for replacing scales include:

-

Inconsistent readings

-

Failure to return to zero

-

Discrepancies when weighing known weights

-

Physical damage to the scale or its components, which is also a strong signal that an upgrade is necessary.

Frequent errors or the need for adjustments may indicate that your scale is no longer reliable. Scales that frequently require recalibration due to environmental factors like temperature and humidity should also be considered for replacement. Ensuring your scales can handle the required accuracy for specific applications or industries is paramount for maintaining operational efficiency, compliance, and preventing inaccurate readings.

Summary

In summary, NTEP compliance is crucial for any business involved in commercial transactions based on weight. Using NTEP-certified scales ensures that businesses adhere to legal standards, avoid fines, and maintain trust with customers. The benefits of using accurate and reliable weighing equipment extend beyond compliance, enhancing operational efficiency and reducing long-term costs.

By understanding the importance of NTEP compliance, the certification process, and the different types of NTEP-approved scales, businesses can make informed decisions that ensure legal compliance and operational success. Investing in quality equipment and maintaining regular calibration and maintenance practices will help businesses stay ahead and avoid unnecessary legal and financial risks. Stay compliant, stay efficient, and build a reputation for accuracy and reliability in every transaction.

Frequently Asked Questions

What is NTEP compliance?

NTEP compliance signifies that weighing devices have passed a certification process to ensure they meet strict accuracy and performance standards for commercial use. This compliance is crucial for maintaining fairness in trade.

What are the benefits of using NTEP-approved scales?

Using NTEP-approved scales enhances consumer trust and minimizes transaction errors, ensuring accurate pricing and operational efficiency. This leads to financial integrity and reliability in commercial transactions.

How does the NTEP certification process work?

The NTEP certification process entails submitting an application to the National Conference on Weights and Measures (NCWM), followed by a laboratory evaluation. If the device meets the established standards, it is awarded a Certificate of Conformance.

What types of NTEP-approved scales are available?

NTEP-approved scales encompass a variety of options such as floor scales, portable pallet scales, load cells, and precision balances, each tailored for specific commercial applications. These devices are recognized for their accuracy and compliance with trade regulations.

When should I upgrade my weighing equipment?

You should upgrade your weighing equipment if it displays inconsistent readings, frequently errors, suffers from physical damage, or requires constant recalibration due to environmental impacts. Timely upgrades ensure accuracy and reliability in your measurements.