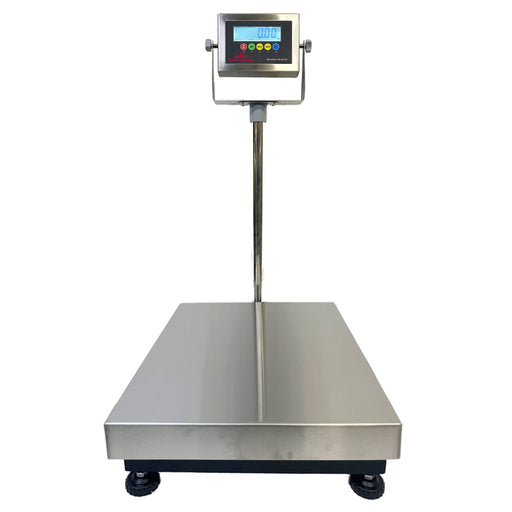

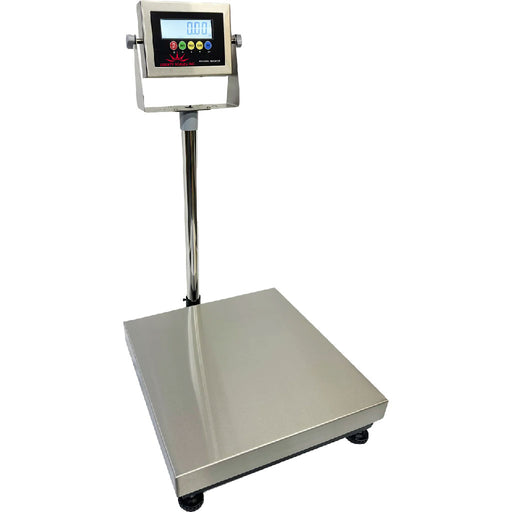

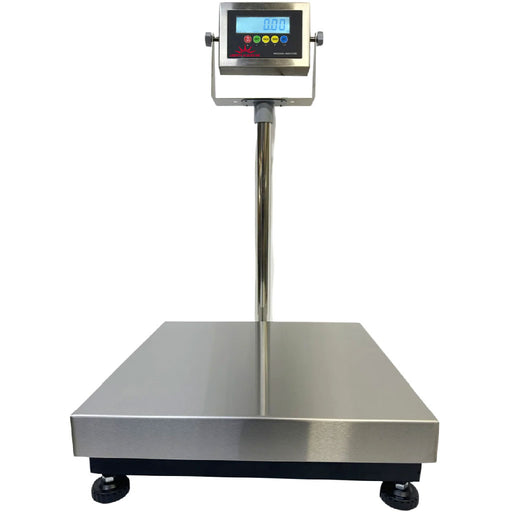

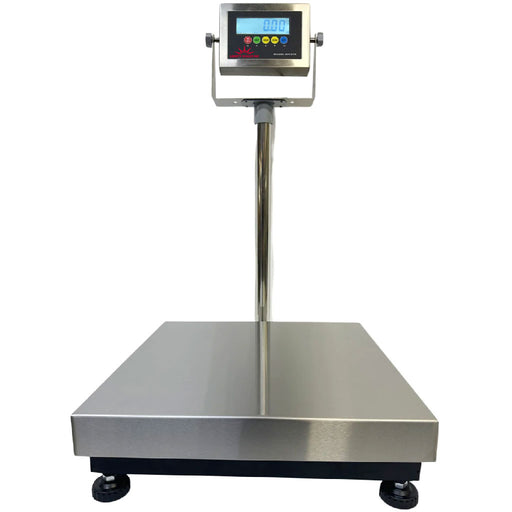

Industrial Bench Scales are a cornerstone in various industrial settings, designed for durability, versatility, and precision. These scales are engineered to endure heavy-duty usage, making them ideal for manufacturing, warehousing, and more, where accurate weight measurements are vital for quality control and inventory management.

Our selection offers a range of scales to suit diverse industrial needs. This includes robust Industrial Bench Scales for handling substantial loads and portable Bench Scales for those requiring mobility without sacrificing accuracy. Most of our Bench Scales come with Stainless Steel Indicators for easy and efficient weight readings. Additionally, we feature Bench Scales with locking casters for movable stability and Stainless Steel Bench Scales for environments demanding hygiene and corrosion resistance.

Catering to a broad spectrum of weighing tasks, our collection ensures that businesses can find a reliable, precise weighing solution, enhancing operational efficiency and product quality.

We also offer Legal for Trade Bench Scales, please visit our NTEP-certified Bench Scales collection.