Multipack Floor Scales: Complete Guide to Bulk Industrial Weighing Solutions

When your business operations require multiple weighing stations across various locations, investing in individual floor scales can quickly become costly and inefficient. Multipack floor scales offer a strategic solution for businesses seeking to streamline their weighing processes while achieving significant cost savings through bulk purchasing.

These comprehensive weighing packages are engineered specifically for industrial environments where consistent accuracy and reliable performance across multiple stations are essential. Whether you’re managing a warehouse, manufacturing facility, or distribution center, understanding the advantages and applications of multipack floor scales can transform your operational efficiency while reducing long-term costs.

In this complete guide, we’ll explore everything from the fundamental benefits of bulk purchasing to specific configurations, technical specifications, and real-world applications that make multipack floor scales an ideal solution for modern industrial operations.

What Are Multipack Floor Scales

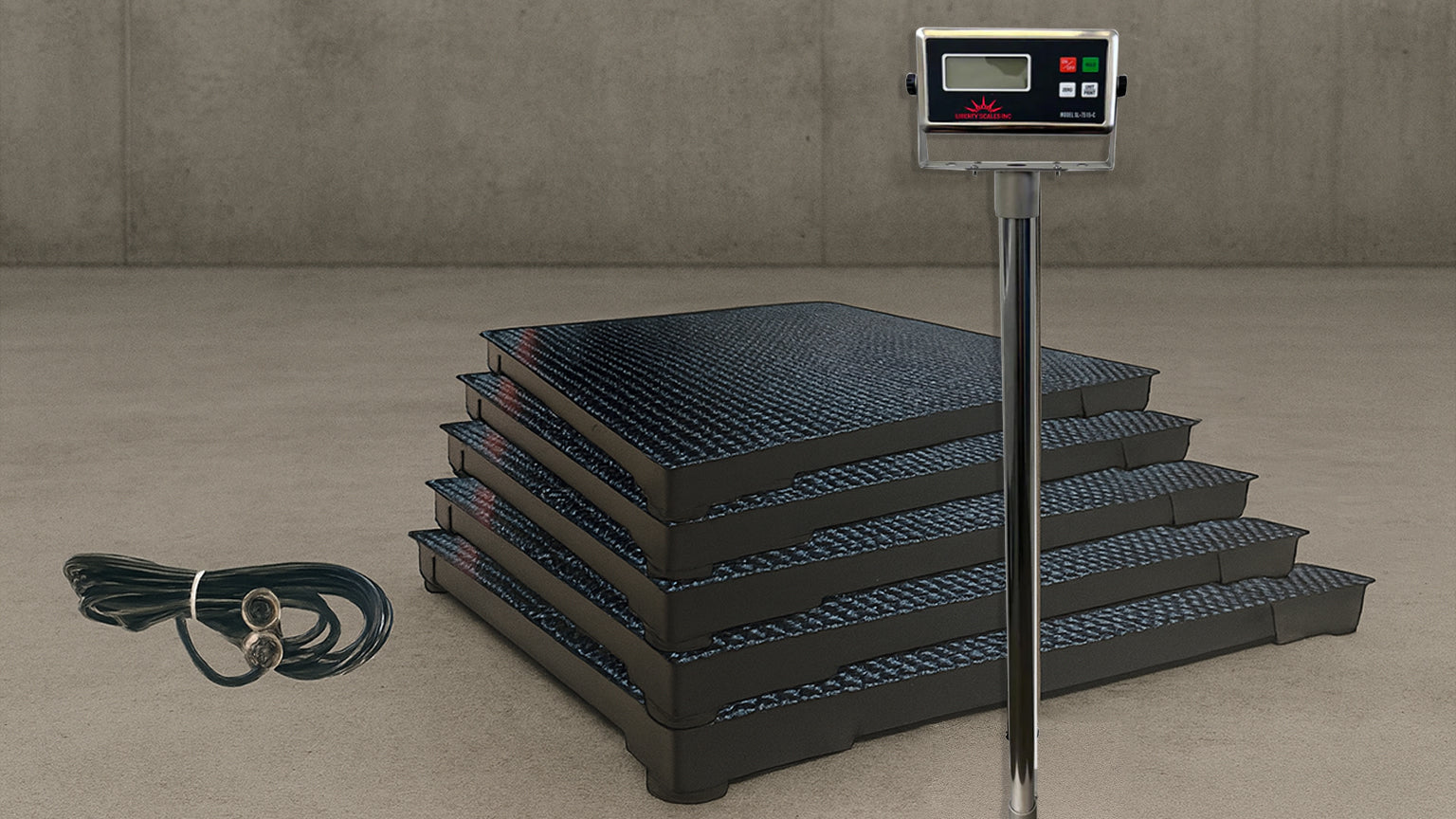

Multipack floor scales represent bulk purchasing options for industrial weighing equipment, typically offering combinations of multiple floor scale units packaged together at discounted rates. These packages commonly feature 5x and 10x multipack configurations, allowing businesses to equip multiple locations or workstations with identical weighing capabilities.

The core advantage of multipack options lies in their cost-effective approach to large-scale weighing infrastructure. Rather than purchasing individual scales as needs arise, businesses can strategically invest in comprehensive weighing solutions that address current requirements while planning for future expansion.

When comparing single unit purchases versus multipack options for industrial operations, the differences extend beyond simple cost considerations. Single purchases often result in inconsistent equipment specifications across facilities, varying maintenance schedules, and complex inventory management for spare parts and calibration services.

Multipack floor scales ensure standardization across all weighing operations, creating a unified system where technicians can service any unit with the same procedures and replacement components. This standardization proves particularly valuable for businesses operating multiple facilities or those requiring precise weight measurements across different production lines.

Benefits of Purchasing Multipack Floor Scales

The primary advantage of multipack floor scales centers on substantial cost savings through bulk pricing discounts compared to individual scale purchases. Most suppliers offer significant reductions when customers commit to larger quantities, with savings often ranging from 15% to 30% depending on the specific package size and configuration.

Operational efficiency gains represent another crucial benefit, as having multiple weighing stations across facilities eliminates bottlenecks in production and shipping processes. Instead of workers waiting in line to use a single scale, multiple stations enable simultaneous weighing processes that dramatically reduce processing time and improve overall workflow.

Standardization benefits ensure consistent accuracy and performance across all units within your operation. When every scale operates with identical specifications, calibration procedures, and maintenance requirements, your team can achieve predictable results regardless of which station they’re using. This consistency proves essential for quality control processes and regulatory compliance in industries requiring precise weight measurements.

Reduced procurement time and administrative overhead for large-scale operations streamline the purchasing process significantly. Rather than managing multiple purchase orders, vendor relationships, and delivery schedules, multipack purchases consolidate everything into a single transaction with coordinated delivery and installation services.

Enhanced workflow capabilities enabling simultaneous weighing processes transform operational capacity. Manufacturing facilities can implement multiple quality control checkpoints, warehouses can process shipments more efficiently, and distribution centers can handle higher volumes without adding labor costs.

Popular Multipack Floor Scale Configurations

Understanding the most common multipack sizes and their applications helps businesses select the optimal configuration for their specific needs. Each size category offers distinct advantages depending on the types of materials being weighed and the available workspace.

24” x 24” (2x2) Multipack Floor Scales

These compact units serve as ideal solutions for smaller items and compact workspace requirements where floor space comes at a premium. The 24” x 24” platform size accommodates most standard shipping boxes, components, and packaged goods while maintaining the heavy duty construction necessary for industrial environments.

Capacity ranges typically span from 1,000 to 10,000 lbs with 1 lb increments, providing the precision needed for parts counting, small package weighing, and quality control stations. The smaller footprint makes these scales particularly suitable for production lines where multiple weighing points are required without disrupting workflow.

Food processing facilities often deploy these configurations at ingredient measurement stations, while electronics manufacturers use them for component verification and inventory management. The high precision capabilities ensure accurate measurements even for lightweight items, making them versatile solutions for diverse industrial applications.

36” x 36” (3x3) Multipack Floor Scales

The 36” x 36” configuration represents the most versatile size for general industrial applications and warehouse operations. This platform size strikes an optimal balance between workspace requirements and weighing capacity, accommodating everything from individual packages to small pallets.

Capacity options from 1,000 to 30,000 lbs accommodate diverse weighing needs across different industries. The larger platform surface area provides stability for irregularly shaped items while maintaining the precision necessary for shipping verification and inventory management.

These scales excel in shipping departments where packages of varying sizes require accurate weight measurement for shipping charges calculation. The platform size easily handles oversized items that wouldn’t fit on smaller scales, while the capacity range supports everything from lightweight packages to heavy machinery components.

Distribution centers frequently implement multiple 36” x 36” stations throughout their facilities, creating efficient weighing zones that support high-volume operations without creating bottlenecks in the shipping process.

Large Format Multipack Options

For businesses dealing with oversized items and heavy-duty applications, large format multipack options provide the platform space and capacity needed for specialized industrial requirements. These configurations include 48” x 96” (4x8) scales designed for lengthy items like lumber, steel beams, or large machinery components.

The 60” x 84” (5x7) configurations serve specialized industrial requirements where standard rectangular platforms don’t provide optimal weight distribution. These scales often feature custom load cell positioning to ensure accurate readings regardless of load placement on the platform.

72” x 72” (6x6) scales designed for maximum platform space and heavy loads can accommodate full pallets, large containers, and heavy machinery. The substantial platform area ensures proper weight distribution while the reinforced construction handles capacities often exceeding 50,000 lbs.

These large format options frequently include specialized features such as approach ramps, pit installation capabilities, and enhanced environmental protection for outdoor use. The multipack approach for large scales provides substantial cost savings, as individual large-capacity scales represent significant investments when purchased separately.

Industrial Applications for Multipack Floor Scales

Manufacturing facilities requiring multiple production line weighing stations benefit significantly from standardized multipack implementations. Quality control processes demand consistent accuracy across all measurement points, making identical scale specifications essential for maintaining product standards and regulatory compliance.

Automotive manufacturers often deploy multipack floor scales throughout assembly lines for component verification, while pharmaceutical companies use them for ingredient batching and finished product verification. The ability to integrate multiple scales with centralized data collection systems enables comprehensive tracking and documentation required in regulated industries.

Warehouse operations for inventory management and shipping verification represent perhaps the most common application for multipack floor scales. These facilities require multiple weighing stations to handle diverse package sizes and weights efficiently while maintaining accurate records for inventory control and shipping charges calculation.

The standardization achieved through multipack purchases ensures that warehouse workers can operate any scale with identical procedures, reducing training time and minimizing errors. Integration capabilities allow weight data to flow directly into warehouse management systems, eliminating manual data entry and improving accuracy.

Distribution centers handling high-volume package processing rely on multipack floor scales to maintain throughput while ensuring shipping accuracy. Multiple weighing stations prevent bottlenecks during peak shipping periods, while consistent accuracy across all scales ensures proper shipping method selection and cost calculation.

Agricultural operations for bulk commodity weighing and grain handling utilize large-capacity multipack configurations to process harvest yields, livestock weighing, and feed distribution. The rugged construction required for outdoor agricultural environments makes standardized multipack purchases particularly valuable for ensuring consistent performance across different farm locations.

Construction sites requiring material verification and load monitoring implement portable multipack configurations that can be relocated as projects progress. The ability to verify material quantities and monitor vehicle loads ensures project efficiency while maintaining safety standards for heavy machinery and equipment.

Food processing plants for ingredient batching and portion control deploy multipack floor scales throughout production areas to ensure recipe accuracy and portion consistency. Stainless steel configurations meet hygiene requirements while providing the precision necessary for quality control and regulatory compliance.

Technical Specifications and Features

The construction materials available for multipack floor scales include carbon steel, galvanized steel, stainless steel, and aluminum options, each engineered for specific environmental conditions and application requirements. Carbon steel with epoxy coating provides cost-effective durability for general industrial use, while stainless steel construction ensures compatibility with food processing and pharmaceutical environments.

OIML III compliance standards ensure accuracy and precision across all units within a multipack configuration. This international standard guarantees that each scale meets strict performance criteria for commercial weighing applications, providing the reliability necessary for business operations and regulatory compliance.

Power requirements typically utilize 5 ± 0.5VDC for enhanced precision and reliability, with options for battery operation in portable applications or direct AC power for permanent installations. The standardized power requirements across multipack units simplify electrical installation and maintenance procedures.

Load cell specifications and junction box configurations vary depending on environmental requirements and capacity needs. Hermetically sealed load cells provide protection against moisture and contaminants, while IP69K-rated junction boxes ensure reliable operation in washdown environments.

Digital indicators with LCD displays offer clear weight readouts with customizable increments and decimal places for specific weighing requirements. Optional scoreboard attachments provide remote weight display capabilities, allowing operators to read weights from a distance or enabling customer verification during transactions.

Advanced features include data logging capabilities, statistical functions for quality control, and checkweighing modes that alert operators when weights fall outside predetermined ranges. These features prove particularly valuable in manufacturing environments where process control and quality assurance are critical.

Installation and Setup Options

Portable installation options provide flexible positioning and easy relocation capabilities, making them ideal for facilities where weighing requirements change frequently or where temporary installations are needed. Portable configurations typically include integrated ramps and forklift channels for easy access without requiring permanent modifications to facility floors.

The versatility of portable installations allows businesses to optimize scale placement based on workflow changes, seasonal demands, or facility reconfigurations. This flexibility represents a significant advantage for growing businesses or those with evolving operational requirements.

Permanent in-ground pit frame installations serve high-traffic areas where flush-mounted platforms provide seamless integration with existing floor surfaces. These installations eliminate the need for ramps while providing stable, long-term weighing solutions for facilities with consistent, high-volume weighing requirements.

Pit installations require careful planning and professional installation but offer superior durability and integration with facility operations. The flush-mounted design reduces trip hazards and allows for smooth material handling equipment operation across the scale platform.

Above-ground mounting options with ramp systems provide easy access while maintaining the flexibility to relocate scales if needed. These installations offer a compromise between permanent pit installations and fully portable solutions, providing stability and ease of use without requiring extensive floor modifications.

Software integration capabilities for data management and record keeping enable seamless connection with existing business systems. Modern multipack floor scales can connect directly to ERP systems, warehouse management software, and quality control databases, eliminating manual data entry and improving accuracy.

Printer connectivity options for immediate weight documentation provide instant record-keeping capabilities essential for shipping verification, quality control, and regulatory compliance. Network connectivity features enable centralized monitoring systems that allow management to track usage, performance, and maintenance requirements across all scales in the multipack configuration.

Environmental Considerations and Upgrades

Indoor versus outdoor installation requirements significantly impact material selection and protective features needed for reliable performance. Indoor installations typically utilize standard carbon steel construction with epoxy coating, while outdoor applications require galvanized or stainless steel construction for corrosion resistance.

Stainless steel components for corrosive or humid environments provide enhanced durability in challenging conditions. Food processing facilities, chemical plants, and coastal installations benefit from stainless steel construction that resists corrosion and maintains accuracy over extended periods.

IP-rated enclosures for electronics protection in harsh conditions ensure reliable operation in dusty, wet, or corrosive environments. IP67 and IP69K ratings provide protection against water ingress during washdown procedures, making these scales suitable for food processing and pharmaceutical applications.

Temperature compensation features maintain accurate readings across climate variations, ensuring consistent performance regardless of seasonal temperature changes or process-related temperature fluctuations. This feature proves particularly important for outdoor installations or facilities with significant temperature variations.

Washdown capabilities for food processing and pharmaceutical applications include sealed load cells, stainless steel construction, and sloped surfaces that facilitate cleaning and sanitization. These features ensure compliance with hygiene standards while maintaining weighing accuracy.

Specialized coatings and treatments can provide additional protection against specific chemicals or environmental conditions. Custom environmental upgrades ensure that multipack floor scales maintain reliable performance regardless of challenging operating conditions.

Cost Analysis and ROI Considerations

The breakdown of multipack pricing advantages versus individual purchases reveals substantial savings opportunities for businesses requiring multiple weighing stations. Bulk purchasing typically reduces per-unit costs by 15% to 30%, with larger multipacks offering proportionally greater savings.

Beyond initial purchase price reductions, multipack configurations provide additional cost benefits through standardized installation procedures, coordinated delivery schedules, and unified warranty coverage. These factors reduce administrative overhead and simplify vendor management compared to multiple individual purchases.

Total cost of ownership analysis must include installation, maintenance, and calibration costs over the equipment’s expected lifespan. Multipack purchases often include volume discounts on installation services and maintenance contracts, further enhancing long-term value.

Standardized maintenance procedures across identical units reduce technician training requirements and parts inventory needs. This standardization can reduce maintenance costs by 20% to 40% compared to managing diverse scale models with different service requirements.

Productivity gains from reduced weighing time and improved workflow efficiency provide quantifiable returns on investment. Businesses typically see 30% to 50% improvements in weighing throughput when implementing multiple weighing stations compared to single-scale operations.

Reduced inventory shrinkage through accurate weight verification systems helps offset equipment costs through improved inventory control. Accurate weighing reduces shipping errors, minimizes customer complaints, and ensures proper billing for shipped products.

Long-term durability benefits reduce replacement costs over time, as industrial-grade multipack floor scales typically provide 10 to 15 years of reliable service with proper maintenance. The standardization achieved through multipack purchases ensures consistent performance and replacement scheduling across all units.

Financing options and lease programs available for large multipack purchases help businesses manage cash flow while acquiring necessary weighing infrastructure. Many suppliers offer attractive financing terms for substantial multipack orders, making it easier for businesses to implement comprehensive weighing solutions without significant upfront capital investment.

The return on investment for multipack floor scales typically becomes apparent within 12 to 18 months through operational efficiency gains, reduced labor costs, and improved accuracy in shipping and inventory management. For businesses processing high volumes or operating multiple facilities, the ROI period often shortens to 6 to 12 months due to substantial productivity improvements and cost savings.

When evaluating multipack floor scales for your operation, consider not only the immediate cost savings but also the long-term operational benefits of standardized, reliable weighing infrastructure. The combination of reduced equipment costs, improved efficiency, and enhanced accuracy makes multipack floor scales a strategic investment that delivers measurable returns while supporting business growth and operational excellence.